- Home Page

- Company Profile

-

Our Products

- Printed Packaging Materials

- Flexible Packaging Materials

- Paper Packaging Materials

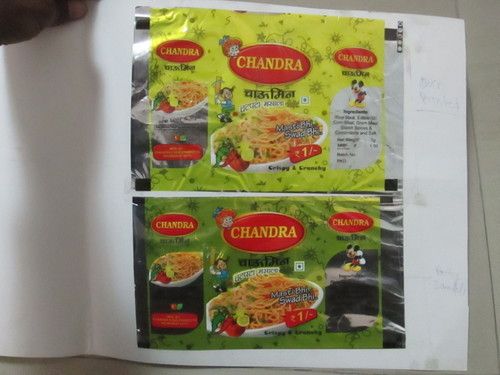

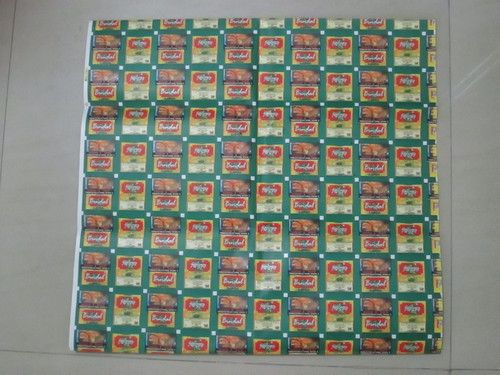

- Printed Pouches

- Laminated Packaging Pouches

- Food Packaging Materials

- Printed Polyester Wrapper

- Polyester Pouch

- Food Packaging Materials

- Sai Prasad Packaging Material

- Spices Packaging Material For Food Industry

- Coconut Powder Packaging Pouch

- Masala Laminated Pouches

- Salt Packaging Pouch

- Makhana Packaging Pouch

- Pulses Packaging Bags

- Elachi Packaging Pouch

- Frozen Food Packaging Bag

- Spices Printed Packaging Pouches

- Laminated Namkeen And Wafers Pouch

- Garam Masala Powder Packaging Pouch

- Tea Packaging Materials

- Mouth Freshener Packaging Pouch

- Rice Packaging Stand Up Pouch

- Sachets Packing Material

- Printed Sachet Packing Material

- Candy Packaging Pouch

- Prasad Packaging Material

- Instant Coffee Premix Pouch

- Chocolate Laminated Pouch

- Tea Packaging Bag

- Dry Fruit Packaging Bags

- Besan Pouches Packaging Materials

- Coffee Packaging Bags

- Mouth Freshener Pouches And Roll

- 5kg Atta Pouch

- Vacuum Packaging Pouch

- Spices Powder Laminated Packaging Roll

- Kurkure Pouch

- Flour Packaging Pouches

- Gram Flour Packaging Pouches

- Buiscuit Packaging Pouches

- Cardomom Packaging Pouches

- Candy Packaging Pouch

- Chips Packaging Rolls

- Chocolate Butter Scotch Powder Packaging material

- Chocolate Powder Packaging Material

- Churan Packaging Paper material

- Dry Fruit packaging material

- Food Beverages Packaging Material

- Tea Bags Packaging material

- Baby Cereal Pouches

- Espresso Coffee Powder Packaging Material

- Organic Tea Packaging Material

- Tea and Coffee Packaging Pouches

- Instant Coffee Premix Packaging material

- Instant Milk Premix Packaging material

- Soup Packaging pouches

- Sweets Packaging Pouches

- Food Supplements Packaging Pouch

- Frozen Food Packaging Material

- Ice Cream Packaging

- Ketchup Packaging Material

- Masala Packaging Material

- Turmeric Packaging Pouches

- Non Veg Food Packaging material

- Noodles Packaging Material

- Papad Packaging material

- Pizza Seasoning Packaging Pouches

- Prasad Packaging Material

- Rice Packaging Pouch

- Rusk Packaging Pouches

- Soya Chaap Packaging Bags

- Sugar Packaging Material

- Stevia Sachet Packaging

- Suji Packaging Material

- Poly Coated Paper

- Glassine Poly Coated Paper

- Poly Coated Kraft Paper

- Poly Coated Writing Paper

- Chromo Paper HSL

- Poly Coated Chrome Paper

- Poly Coated Kraft Paper Roll

- Poly Coated Poster Paper

- PE Coated Paper

- Poly Coated LWC Paper

- Pe Coated Maplitho Paper

- Pe Coated Printing Paper

- Poly Coated Art Paper

- Plastic Coated Paper Roll

- Mirror Coated Paper

- Double Sided Pe Coated Paper

- Paper Foil Poly

- Packaging Pouch

- Plastic Food Packaging Bag

- Five Side Seal Pouches

- Laminated Zipper Pouches

- Stand Up Pouch With Window

- HDPE Stand Up Pouch

- Stand Up Foil Pouch

- Zip Lock Stand Up Pouches

- Standup Pouch With Spout

- Plain Pouch Surface Finish Glossy Plastic Pouch

- Stand Up Zipper Pouches

- Flexible Packaging Pouch

- Zip Lock Bags

- Liquid Packaging Pouch

- Side Gusseted Printed Pouches

- Printed BOPP Pouch

- Printed Seal Pouch

- Three Side Seal Pouch

- Poly Bag Pouch

- Silver Metalized Pouches

- Center Seal Pouches Food Packaging

- Bottom Gusset Pouches

- Side Gusset Pouches

- Stand Up Pouches

- Flat Bottom Pouches

- Retort Pouches

- Vacuum Pouches

- Pillow Pouches

- Four Side Seal Pouches

- 3 Side Seal Pouches

- Center Seal Pouches

- Zipper Pouches

- Paper Pouches

- Kraft Pouches

- Transparent Pouches

- Display Pouches

- Stand Up Pouch

- Medical Supplies Packaging Material

- Paper Poly Bulk Mask Packaging

- Masks Packaging Materials

- Food Supplements Packaging Pouch

- Medical Packaging Pouches

- Coated Medical Disposable Apron Fabric

- Alcohol Swab Packaging Material

- Sampling Nylon Flocked Swabs Packaging Material

- Printed Packaging Paper Rolls

- Nutritional Supplements Packaging Material

- Laminated Packaging Rolls

- Woven And Non Woven Packaging Bags

- Agricultural Packaging Material And Pouches

- Cleaning And Sanitary Packaging Material

- Aluminium Foil Paper

- Laminated Pouches

- Poly Coated Paper Based Products

- PE Coated Paper

- Poly Coated Paper

- Poly Coated Paper

- HSL Coated Paper

- Poly Coated Chromo Paper

- Polyester Coated Paper

- LDPE Coated Paper

- HDPE Coated Paper

- Polyester Film Laminated Paper

- Wax Coated Paper

- Poly Coated Poster Paper

- Paper CPP

- Both Side Coated Paper

- Brown Poly Coated Kraft Paper

- Brown Sugar Paper

- Poly Coated Butter Paper

- Poly Coated Chromo Paper

- Poly Coated Glassine Paper

- Poly Coated Kraft Paper

- Poly Coated Maplitho Paper

- Poly Coated MG Poster Paper

- Poly Coated Semi Kraft paper

- Poly coated VCI Paper

- Polyester laminated Kraft Paper

- Aluminium Foil Based Products

- Aluminium Foil Laminated Woven Fabric

- Aluminium Foil Laminated Silver Pouch

- Aluminium Foil Pouches

- Aluminum Foil Laminated Paper Bags

- Aluminum Foil Paper Roll

- Aluminum Foil Laminated Non Woven Fabric

- 4 Ply Aluminum Laminates

- Alcohol Swab Packaging Material

- Aluminum Foil Laminate

- Multi-Ply Laminated Aluminium Foil

- Silver Aluminium Foil Laminates

- Aluminium Foil Laminated with Non Woven Fabric

- Paper laminated with Aluminium Foil and HSL

- 3 Ply Laminates

- Aluminum Foil PE laminate

- Aluminum Foil Pouch

- Laminated Aluminum Foil Pouch

- Aluminum Foil Stand Up Pouch

- Aluminum Foil Laminated Silver Pouch

- Non Woven Fabric Laminated Products

- Non Woven Fabric Laminated Aluminum Foil

- Non Woven Fabric laminated with Printed BOPP

- Printed BOPP Laminated Non Woven Fabric

- Plain polyester Laminated Non Woven fabric

- Plain laminated Non Woven Fabric Roll

- Laminated Non Woven Fabric

- PE Coated Hydrophillic PP SpunBond Non Woven Fabric

- Paper Laminated Non Woven Fabric

- Metalize Film Laminated Non Woven Fabric

- Poly Coated Non Woven Fabric

- BOPP Laminated Non Woven Fabric

- Woven Fabric Based Products

- Printed Plastic Packaging Material

- Packaging Material

- Met Pet Laminated With Woven Fabric

- Silver Pouches

- Polyester Packaging Pouch

- Printed Laminated Pouch

- Packaging Pouch

- Flexible Packaging Pouch

- Flexible Packaging Rolls

- Lamination Pouches

- Printed Plastic Pouch

- Printed Packaging Pouch

- Packaging Board

- Plain Glossy Aluminium Zipper Pouch

- Printed Laminated Pouches

- Laminated Polyester Pouches

- Normal Pouch

- Plain Vacuum Laminated Pouches

- Printed Glossy Food Pouches

- LDPE Laminated Zipper Pouch

- Plain Laminated Zipper Pouch

- Pet (Polyester) Silver Pouch

- Rotogravure Printed Pouches

- Vacuum Food-Grade Packaging Pouches

- Gold Lamination Pouch

- Home and Cleaning Products

- Fabric Softener Packaging Material

- Shampoo and Conditioner Packaging Material Pouch

- Body Wash Packaging Pouch

- liquid Soap Detergent Printed Packaging pouch

- Liquid Soap Pouch

- Soap Bar Packaging Pouch

- Soap Wrapper Paper Packaging Material

- Utensil Washing Soap Packaging Pouch

- Hand Soap Packaging Pouch

- Shampoo Sachet

- Sports Wear Packaging Pouches

- Health & Beauty

- Alcohol Swab Packaging Material

- Bandage Strip Packaging Material

- Tablet Strip Packaging Material

- Surgical Hand Gloves Packaging Material

- Hand Gloves Packaging Material

- Hand Sanitizer Packaging Material

- Medicines Packaging material

- ORS Packaging material

- Surgical Mask Packaging Material

- Mask Packaging Material

- Swab Packaging Material

- Industrial Packaging Material

- Nuts Bolts and Screws Packaging Pouches

- PVC Wires and Cables Packaging

- House Wiring Cables Packaging material

- Industrial Wiring Cables Packaging material

- Auto Parts Packaging Material

- Lubricants and Oils Packaging material

- Industrial Packaging material

- Piston Rings Paper Packaging Pouches

- Cable Clip Pouches

- Gypsum Plaster Packaging

- Colour packaging material

- Disposable Wrapper Paper

- Distemper Powder Packaging Material

- Electric Wire Packaging Material

- Cables and Wires Packaging Material

- Napthalene Balls Packaging material

- Paint Packaging Material

- Painting Roller Packaging Material

- Piston Ring Packaging Material

- Silicone wire Packaging material

- wall putty Packaging Pouches

- White Cement Packaging Material

- Wires and Cable Packaging material

- Cell Phone Accessories Packaging Pouches

- USB Cable Packaging Pouches

- Agricultural Products

- Contact Us

Silicone Coated Paper

160.00 - 260.00 INR/Kilograms

Product Details:

- Product Type Silicone coated release paper

- Material Silicone coated paper

- Type Release liner

- Style Single-sided or double-sided coating

- Packing Format Sheets and rolls

- Hardness Standard paper hardness

- Tensile Strength High (suitable for lamination and converting processes)

- Click to View more

X

Silicone Coated Paper Price And Quantity

- 160.00 - 260.00 INR/Kilograms

- 1000 Kilograms

Silicone Coated Paper Product Specifications

- Single-sided or double-sided coating

- Standard paper hardness

- Silicone coated release paper

- Silicone coated paper

- Release liner

- White or custom (as required)

- Sheets and rolls

- Standard and custom sizes available

- High (suitable for lamination and converting processes)

- Varies (customizable as per requirement)

Silicone Coated Paper Trade Information

- 300 Kilograms Per Day

- 7-10 Days

Product Description

Established in the year 2003, we have established as a reliable manufacturer and supplier of Silicone Coated Paper. By using ultra-modern machinery, we manufacture the offered coated paper in compliance with the packaging industry laid norms and regulations. With our strong logistic support, we have been able to deliver the offered Silicone Coated Paper at the patrons end within the assured time frame.

Applications:

-

Chemical industry

-

Cosmetic industry

-

Food processing industry

Versatile Release Liner Solutions

Silicone Coated Paper offers an optimal balance of durability, printability, and reliable release properties. It serves a wide range of industries, from tapes and stickers to hygiene and food sectors, thanks to its customizable features. Both single- and double-sided coating options are available to meet specific technical and functional demands.

High-Performance and Customization

Manufactured using premium base paper and advanced silicone coatings, this product guarantees excellent heat resistance and water repellency. Customers can specify custom colors, dimensions, release levels, and packing formats (sheets or rolls) to suit their operational requirements, ensuring seamless integration into various downstream processes.

FAQs of Silicone Coated Paper:

Q: How is the release level of the silicone coated paper customized for different applications?

A: The release levellow, medium, or highis tailored during production by adjusting the type and amount of silicone polymer used. This allows the liner to meet the specific release force required for varying adhesive types in labels, tapes, or hygiene applications.Q: What printing options are available on silicone coated paper for branding or identification?

A: Our silicone coated paper is compatible with various printing techniques, allowing for crisp printing of logos, text, and other graphics as specified by the client. Both pre-printing and post-coating printing options can be accommodated for customized designs.Q: When is silicone coated paper most beneficial in industrial processes?

A: Silicone coated paper is particularly advantageous wherever a reliable release surface is required, such as during manufacturing or application of self-adhesive products, transfer tapes, or medical backings. Its heat and water resistance also make it suitable for environments with demanding processing conditions.Q: Where can this silicone coated paper be used within the hygiene and medical industries?

A: In the hygiene and medical fields, this paper is commonly utilized as backing for medical tapes, drapes, or disposable items, offering easy separation and excellent handling while maintaining product sterility and safety standards.Q: What are the recommended storage conditions to maximize shelf life?

A: To preserve quality, silicone coated paper should be stored in a cool, dry area, away from direct sunlight and humidity. Under proper conditions, it will maintain functionality for between 12 to 24 months.Q: How does the manufacturing process ensure consistent quality and environmental compliance?

A: The product is manufactured in an ISO-certified facility, guaranteeing strict adherence to quality control procedures. Furthermore, all materials are selected for recyclability, supporting sustainable usage and meeting stringent industry standards.Q: What advantages does using silicone coated paper bring to converting and lamination processes?

A: Due to its high tensile strength and stable release properties, silicone coated paper enables smooth processing in converting and lamination operations, reducing waste and ensuring clean, efficient production cycles.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Printed Pouches' category

We are accepting bulk order quantity only.