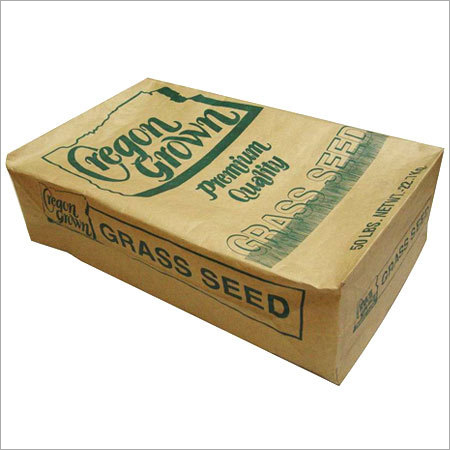

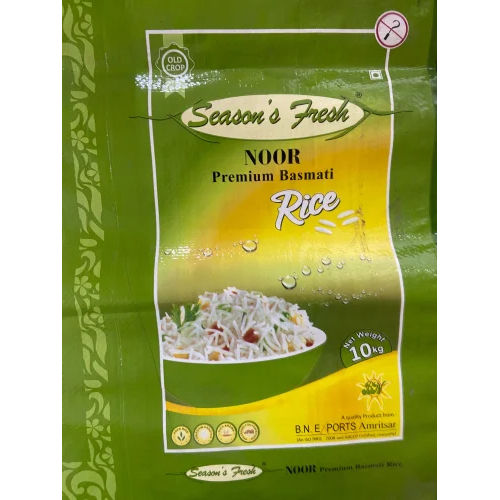

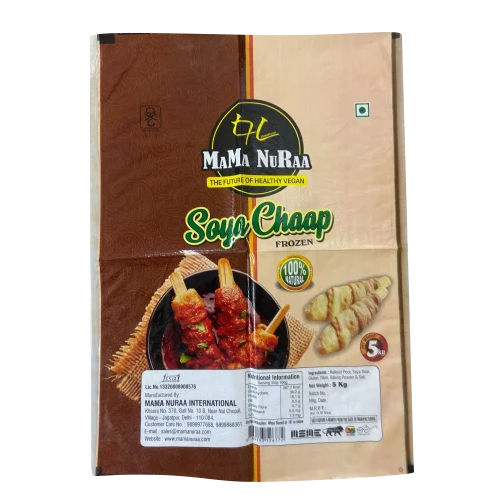

Paper Poly Laminated Bags

100.00 - 150.00 INR/Kilograms

Product Details:

- Paper Type Kraft Paper (Virgin/Recycled, 1-4 ply options)

- Handles Without handles

- Surface Handling Poly Lamination, Offset Printing, Flexographic Printing

- Style Open mouth, stitched or glued bottom, gusseted

- Size Customizable, standard sizes available: 25kg, 50kg

- Max Load Up to 50 kg

- Color White, Brown, Custom printed

- Click to view more

X

Paper Poly Laminated Bags Price And Quantity

- 100.00 - 150.00 INR/Kilograms

- 1000 Kilograms

- 1 to 3 Ply (with or without poly lamination)

- Flexographic or Gravure up to 6 colors

- 60 to 120 GSM (depending on ply and lamination)

- Flat or Gusseted

- Packaging of Chemicals, Food Grain, Seeds, Animal Feed, Fertilizers, Cement

- Enhanced due to poly lamination

- Polyethylene for extra moisture protection

- Stitching (top hemmed), Heat Sealed (optional)

- Recyclable and Eco-friendly (on request)

Paper Poly Laminated Bags Product Specifications

- Open mouth, stitched or glued bottom, gusseted

- Customizable, standard sizes available: 25kg, 50kg

- Poly Lamination, Offset Printing, Flexographic Printing

- Up to 50 kg

- Without handles

- White, Brown, Custom printed

- Moisture Proof, Durable, High Strength

- Yes, available as per customer requirement

- Kraft Paper (Virgin/Recycled, 1-4 ply options)

- 1 to 3 Ply (with or without poly lamination)

- Flexographic or Gravure up to 6 colors

- 60 to 120 GSM (depending on ply and lamination)

- Flat or Gusseted

- Packaging of Chemicals, Food Grain, Seeds, Animal Feed, Fertilizers, Cement

- Enhanced due to poly lamination

- Polyethylene for extra moisture protection

- Stitching (top hemmed), Heat Sealed (optional)

- Recyclable and Eco-friendly (on request)

Paper Poly Laminated Bags Trade Information

- 300 Kilograms Per Month

- 7-10 Days

Product Description

By adhering to all the set quality norms of the industry, we have becoming a pioneer manufacturer, supplier, wholesaler of a wide gamut of Paper Poly Laminated Bags. Our offered laminates are manufactured at our highly developed infrastructure facility under the strict supervision of four adept manpower. Our range of laminated bags are widely used for packet tea, zarda, betal nuts, mosquito mats, medicines, pharmaceutical and surgical items. Our range of Paper Poly Laminated Bags is best known for features such as moisture resistant, easy to use, durable, high strength and many more.

Features :

- Top grade printing

- Excellent moisture barrier

- Puncturing, good to prevent leakage

- Fashionable design,

- Environment friendly materials, high quality,

Superior Moisture Protection and Durability

Our Paper Poly Laminated Bags are engineered with a polyethylene inner liner and poly lamination, offering enhanced moisture resistance and exceptional strength. This design makes them ideal for packaging moisture-sensitive products without compromising structural integrity, even during extended storage and transportation.

Customized Solutions for Diverse Applications

Whether you are packaging chemicals, grains, seeds, fertilizers, or animal feed, our bags are available in customizable sizes and styles to match your requirements. With options for flat or gusseted bags, selectable ply, and printing methods, you can achieve both optimal performance and impactful branding.

Eco-Friendly Packaging Choice

If sustainability is a priority, our paper poly laminated bags can be tailored to be fully recyclable and eco-friendly on request. These bags support environmental initiatives while maintaining product safety and functionality across supply chains.

FAQs of Paper Poly Laminated Bags:

Q: How do poly laminated bags with an inner polyethylene liner provide extra moisture protection?

A: The polyethylene inner liner, combined with poly lamination on the outer surface, forms a reliable barrier against moisture. This dual-layer design prevents water ingress, which is critical for preserving the integrity of products sensitive to humidity, such as food grains and fertilizers.Q: What is the manufacturing process for these bags and how is quality ensured?

A: The bags are crafted using high-strength Kraft paper (1-4 ply, virgin or recycled), with optional poly lamination for added durability. Closures are typically stitched and hemmed at the top, with optional heat sealing. Rigorous quality checks are conducted throughout production to verify strength, moisture resistance, and load-bearing capacity.Q: When should I choose a flat bag versus a gusseted bag?

A: Flat bags are well-suited for uniform, compact products, while gusseted bags expand at the sides, providing extra space for bulkier or irregularly shaped contents. Select the type based on your products physical dimensions and storage requirements.Q: Where can these bags be used most effectively?

A: These bags are ideal for packaging and transporting chemicals, seeds, food grains, animal feed, fertilizers, and cementindustries where moisture-proof, durable containment is essential, especially in the Indian market or for exported goods.Q: What printing and color options are available for customizing these bags?

A: Flexographic or gravure printing up to 6 colors, as well as offset printing, allows for high-quality brand logos and information on white, brown, or custom-colored bags. This flexibility supports your brand visibility and regulatory labeling needs.Q: How do these bags support environmental sustainability?

A: On request, paper poly laminated bags can be manufactured using recyclable and eco-friendly materials without sacrificing durability or performance. This assists companies in meeting green packaging goals while ensuring secure product storage.Q: What are the main benefits of using these paper poly laminated bags?

A: These bags offer moisture-proof protection, high strength, durability, customizable features, versatility (1-3 ply options), and superior printing capabilities. They are suitable for loads up to 50kg and can be tailored for specific application requirements, making them a cost-effective and reliable packaging solution.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Woven And Non Woven Packaging Bags' category

We are accepting bulk order quantity only.

Call Me Free

Call Me Free