Woven Fabric Laminated Bag With Bopp

25 INR/Kilograms

Product Details:

- Product Type Woven Fabric Laminated Bag

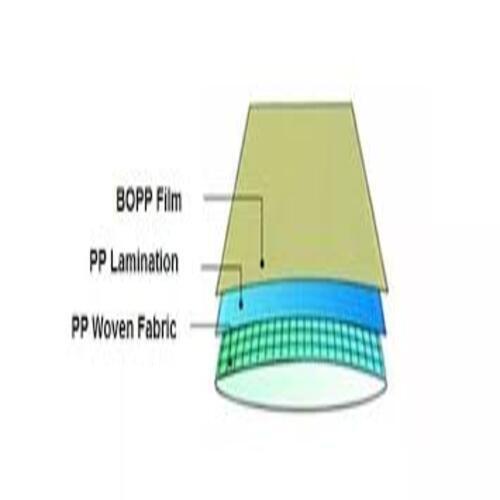

- Material Polypropylene (PP) Woven Fabric, BOPP Film

- Type Laminated

- Style Printed & Plain Available

- Packing Format Laminated Woven Fabric Bag with BOPP

- Hardness Flexible

- Filling Capacity 10 kg to 50 kg (customizable)

- Click to view more

X

Woven Fabric Laminated Bag With Bopp Price And Quantity

- 25 INR/Kilograms

- 1000 Kilograms

- Food grains, seeds, fertilizers, pet food, chemicals

- 10 kg, 20 kg, 25 kg, 50 kg or customized

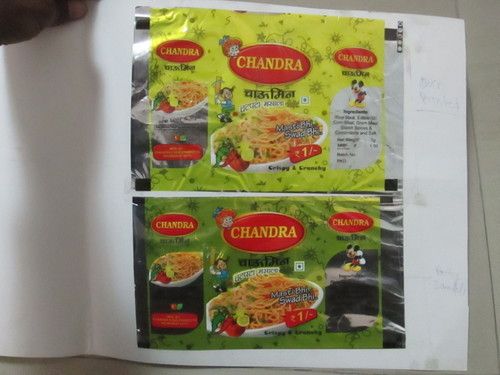

- Custom logo and design possible

- Rotogravure or Flexographic

- Rectangular / Gusseted

- Piece/bundle

- As per material standard

- Glossy/Matte with high-quality print

- High

- Available with UV coating option

- Reusable and recyclable

- Option available (on request)

- Stitched or Heat Sealed

- Excellent due to laminating

- -20°C to +60°C

- Top open or valve

Woven Fabric Laminated Bag With Bopp Product Specifications

- 10 kg to 50 kg (customizable)

- Woven Fabric Laminated Bag

- Flexible

- Printed & Plain Available

- 16 x 24 x 5 (example, customizable)

- Multicolor, as per client design

- Laminated

- N/A (not inflatable)

- Polypropylene (PP) Woven Fabric, BOPP Film

- Laminated Woven Fabric Bag with BOPP

- Available in standard and customized sizes

- N/A (manual bag)

- High, suitable for heavy loads

- Food grains, seeds, fertilizers, pet food, chemicals

- 10 kg, 20 kg, 25 kg, 50 kg or customized

- Custom logo and design possible

- Rotogravure or Flexographic

- Rectangular / Gusseted

- Piece/bundle

- As per material standard

- Glossy/Matte with high-quality print

- High

- Available with UV coating option

- Reusable and recyclable

- Option available (on request)

- Stitched or Heat Sealed

- Excellent due to laminating

- -20°C to +60°C

- Top open or valve

Product Description

We are involved in manufacturing, exporting, distributing & supplying excellent quality Woven Fabric Laminated Bag with BOPP from Sonipat, Haryana, India to our most valued clients. Our offered Woven Fabric Laminated Bag with BOPP is widely appreciated by our clients which are situated all round the nation. We offer Woven Fabric Laminated Bag with BOPP at most affordable prices.Exceptional Durability and Protection

Our laminated bags deliver outstanding puncture and moisture resistance, safeguarding contents against harsh environmental factors. Their robust construction allows the secure storage and transport of heavy loads, making them ideal for industrial and agricultural applications. UV coating further protects products from sunlight, ensuring long-term preservation.

Customizable Branding and Design

Showcase your brand with vivid, high-quality printing and personalized designs available in multicolor options. Whether you require printed logos or unique artwork, these bags accommodate your branding requirements as a manufacturer, supplier, or distributor. Dimensions and capacity can be tailored to ensure optimal utility for your specific market needs.

Eco-Friendly and Reusable Solutions

Opt for eco-friendly packaging with reusable and recyclable woven fabric laminated bags. Engineered for sustainable usage, these bags minimize environmental impact and promote responsible disposal. Upon request, you may choose green alternatives suitable for food, agricultural, and chemical products.

FAQ's of Woven Fabric Laminated Bag With Bopp:

Q: How does the Woven Fabric Laminated Bag with BOPP ensure moisture resistance?

A: The bag's structure features a laminated layer of BOPP film over polypropylene woven fabric, forming a reliable barrier against moisture. This keeps food grains, seeds, fertilizers, and chemicals dry and safe during storage or transport.Q: What printing methods are used for branding and design on these bags?

A: High-quality branding and custom logos are produced using rotogravure or flexographic printing techniques. These allow for glossy or matte finishes with sharp, colorful graphics that stand out and uphold brand identity.Q: When should I choose stitched versus heat-sealed closure for these bags?

A: Stitched closures are suitable for heavy-duty packing and items requiring maximum strength, while heat-sealed closures offer a seamless, tamper-evident finish ideal for products needing airtight packaging. The choice depends on your product requirements and industry standards.Q: Where can these laminated woven bags be used effectively?

A: These bags are widely used by dealers, wholesalers, manufacturers, and retailers in agriculture, animal feed, fertilizer, and chemical sectors across India and beyond. Their versatile sizes and durability make them ideal for both bulk transport and retail display.Q: What is the process for customizing these bags' size, shape, and design?

A: You can specify the desired dimensions, capacity, shape (rectangular or gusseted), and printing details. Manufacturers adapt the bag specifications in production to match your brand, product type, and marketing needs. Customization ensures the best fit for your application.Q: How do these bags benefit distributors and retailers in terms of reusability and eco-friendliness?

A: The reusable and recyclable nature of these bags reduces single-use waste and lowers long-term packaging costs. Offering an eco-friendly option upon request, they appeal to environmentally conscious consumers and support sustainability initiatives.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Printed Pouches' category

We are accepting bulk order quantity only.

Call Me Free

Call Me Free